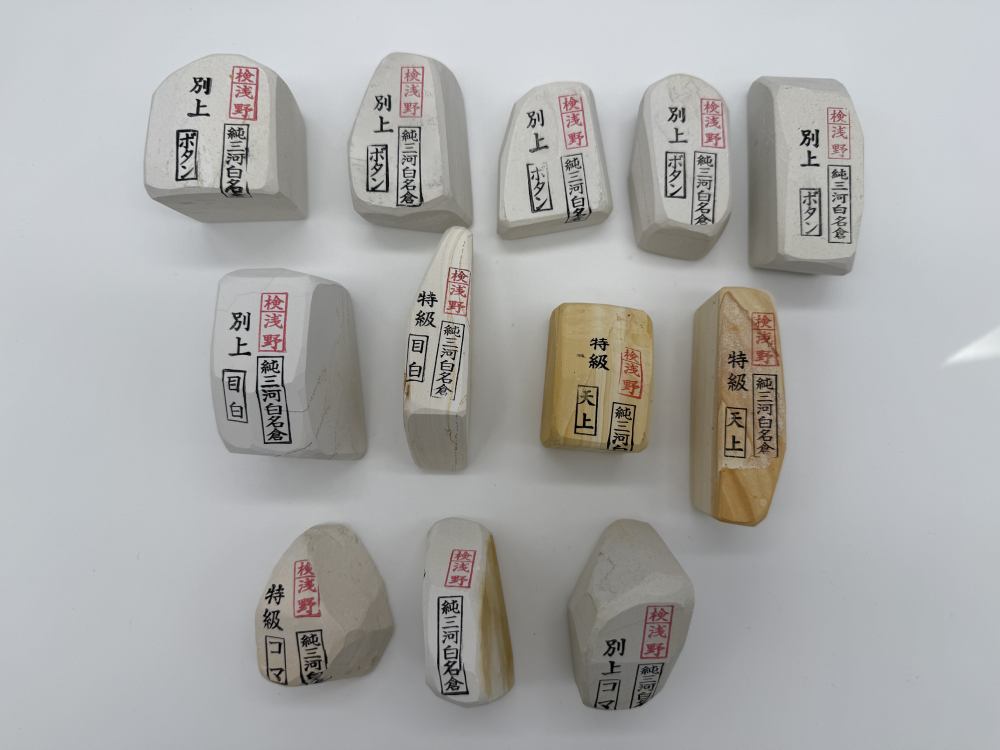

In the world of Japanese natural sharpening stones Nagura stones have a special place. They are not the main sharpening stones, but are designed to create an abrasive suspension on the surface of the main stone, thus extending and enriching the sharpening possibilities. Among them, perhaps the best known and most appreciated system is Asano Mikawa Nagurawhich is distinguished not only by its quality, but also by the thoughtful structure of its progression.

Who is Mikawa Nagura?

Mikawa Nagura - are natural Japanese stones quarried Junmikawa Shiro minelocated at Kitashitara District, Aichi Prefecture. The area has long been known for its light-coloured and finely-textured sedimentary stones, which are ideal for forming abrasive slurries. In total, the mine contains from 10 to 12 geological layersof which 8 considered suitable for nagura stones produce, o 4 of them are the most popular.

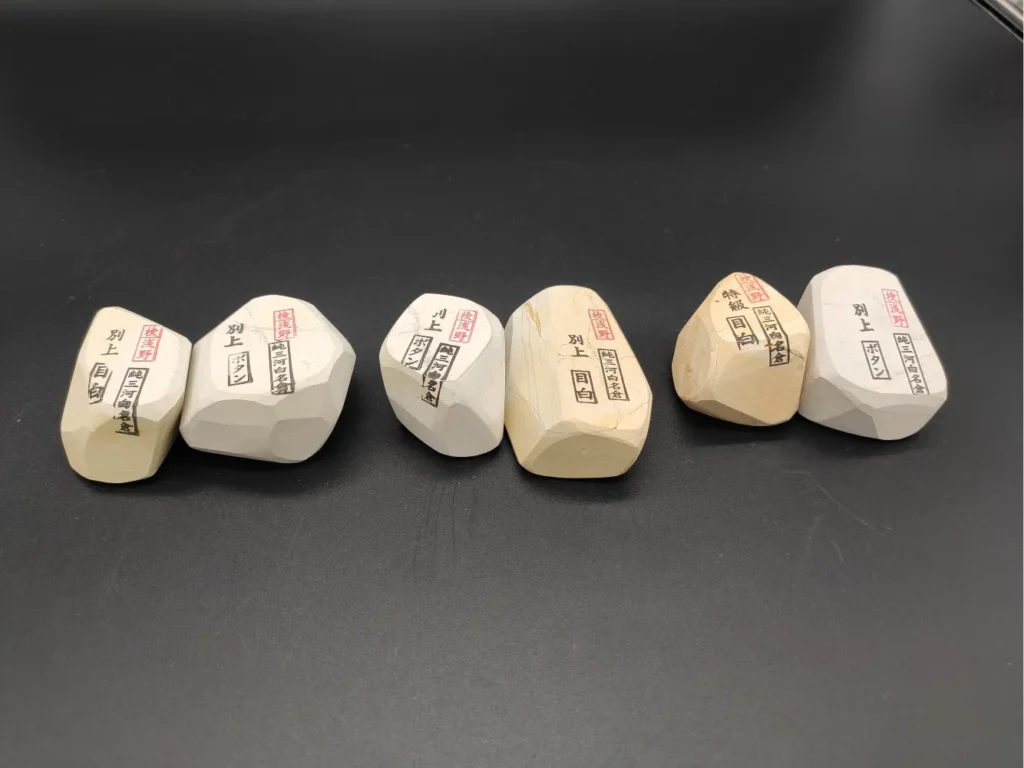

Interestingly, in some areas, even two different Tenjyo layers, as well as Yae Botan and Botanwhich are very similar in characteristics but have subtle differences. Like all natural stones, each specimen of Mikawa nagura is somewhat unique, so small deviations from the standard classification are common.

Asano Mikawa Nagura system

Asana is one of the oldest and most respected families of Nagura preparers. Its uniqueness lies in its attempt to create a free evaluation systemallowing the user to select the desired progression from coarse to fine abrasive.

Although one nail is often enough for the entire sharpening process, as the abrasive particles break down and become finer as they rub together, the Asano system allows for more precise control of the aggressiveness of the abrasive and the grinding speed. The suspension can be renewed with the same burr or switched to a different burr as required.

Exception - Muchi (ムシ)which can usually be too aggressive for delicate blade edges such as razor blades and is generally not recommended for this use.

Classification according to the level of abrasiveness

The Asano Mikawa Nagura are divided from coarsest to finest as follows:

- Mushi (ムシ) - coarsest

- Ban (バン)

- Atsu (アツ)

- Yae Botan (八重ボタン)

- Botan (ボタン)

- Tenjyo (天上)

- Mejiro (目白)

- Koma (コマ) - smallest

Classification according to operating speed

Interestingly, the speed of work does not always coincide with the level of abrasiveness. Asano Mikawa naguli are classified according to work efficiency as follows:

- Ban

- Coma

- Yae Botan

- Botan

- Atsu

- Tenjyo

- Mejiro

This means that some finer nails can work faster than coarser ones, depending on the structure of the stone, the shape of the particles and other properties. Natural stones are highly individual, so this distinction is not absolute, but has been confirmed in practice in many cases.

Sharpening process with Mikawa Nagura

Sharpening is usually carried out as follows:

- On the main natural sharpening stone form a suspension using the nail of your choice.

- Grinding breaks down the particles and makes the suspension finer.

- When desired, it is possible to switch to a finer nail or to renew the suspension.

- The final stage - sharpening on a clean stone base, without suspension or with a very fine, liquid suspension, resulting in a non-aggressive but hair-precise blade. This method is particularly popular with razor sharpening craftsmen.

Why choose Asano Mikawa Nagura?

- Stable progression from coarse to fine abrasives.

- Adjustable speed.

- The behaviour of the natural particles and the suspension allows the use of a single nail for the whole process.

- Exceptional quality and reliabilitythat the Asano name has guaranteed for decades.

- Traditional origin from Junmikawa Shiro Mine - one of the oldest and most prized sites in Japan.

Nagura can also be a full-size stone used for a medium polishing or sharpening step. They generally have a good working speed and are soft.

Conclusion

Asano Mikawa Nagura - It is not only the stones for creating suspension, but also a whole systematic philosophy for masterfully managing the sharpening process. While modern abrasives can offer standardised performance, the charm of the Mikawa nagura lies in individuality, tradition and precision. These are tools for those who value classic and natural sharpening sensationthat only the rocks of Japan's soil can offer.

Asano Mikawa Nagura table

| Nagura | Level of abrasiveness (from coarsest) | Speed of operation | Recommended use |

|---|---|---|---|

| Mushi (ムシ) | 1 (coarsest) | Very fast | For coarser shaping, not always suitable for razors |

| Ban (バン) | 2 | Very fast | For rapid metal grinding, knives, first stage |

| Atsu (アツ) | 3 | Quick | For coarser sharpening work, knives with damaged edges |

| Yae Botan (八重ボタン) | 4 | Medium-fast | For early/intermediate sharpening of knives and razors, removal of smaller defects |

| Botan (ボタン) | 5 | Medium | The main sanding step before moving on to finer nails |

| Tenjyo (天上) | 6 | Slow | For fine sharpening, a transitional stage before Mejiro |

| Mejiro (目白) | 7 | Very slow | For final sharpening, delicate edge smoothing, before Koma or clean stone |

| Koma (コマ) | 8 (smallest) | Medium-Slow | Last step before final polishing on clean stone, very fine work, especially suitable for razors and precision knife finishing |

Brief explanations:

- Level of abrasiveness: indicates the coarseness of the stone particles. The lower the number, the coarser the abrasive.

- Speed of operation: how quickly the nagura removes metal. Does not always correspond to the level of abrasiveness.

- Recommended use: traditional and modern methods of the masters.

Things to know:

- Tenjyo layer in some parts of Junmikawa, it has two different variations - one more abrasive, the other softer.

- Yae Botan and Botan are very similar, but Yae Botan usually act slightly faster and more aggressively.

- The colour of the suspension can vary from whitish to yellowishdepending on the porosity of the stone and the specific layer.