Introduction

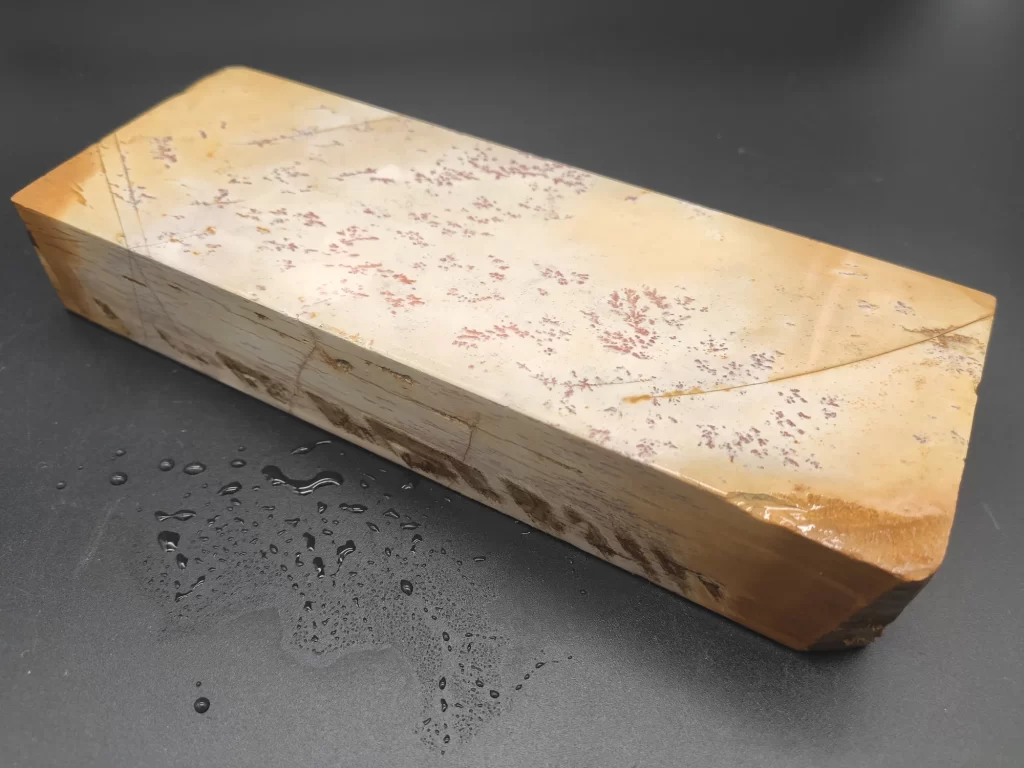

Natural Japanese whetstones are one of the oldest and most refined sharpening traditions in the world. They are valued not only for their exceptional abrasive properties, but also for their historical heritage, stone structure, place of origin and even the reputation of the mine. In this guide, we will discuss everything you need to know about Japanese natural stones: their types, mines, features of use, selection and care.

What are Japanese natural sharpening stones?

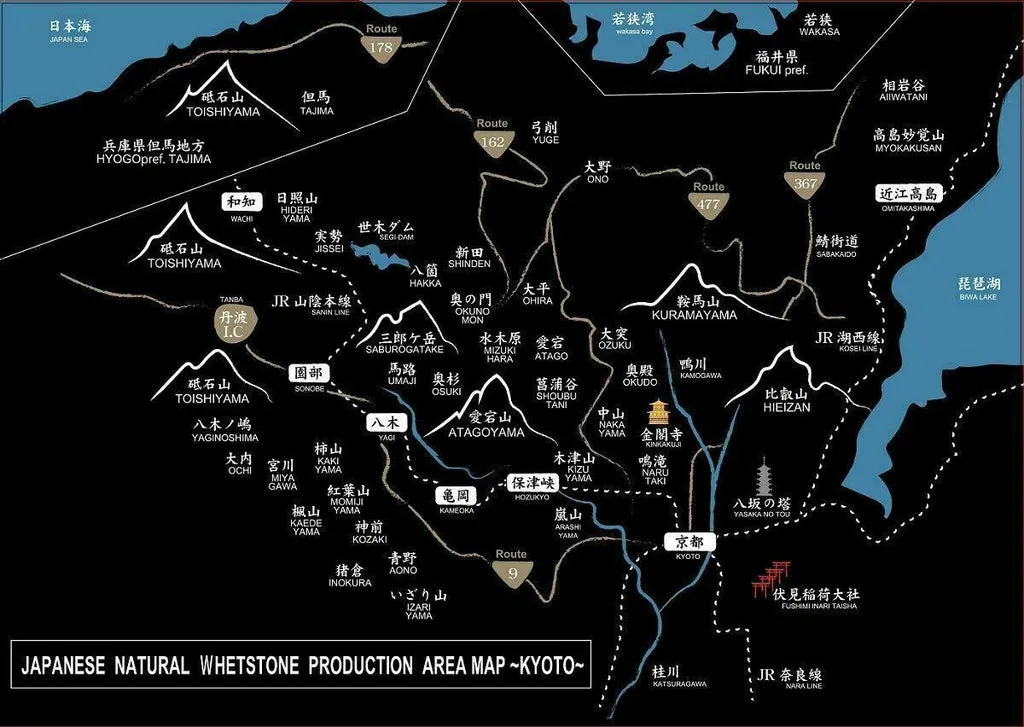

Japanese Natural Whetstones (JNATs for short) are stones quarried in the mountainous regions of Japan, especially around Kyoto, from ancient rock layers formed millions of years ago. They are used to sharpen knives, razor blades, axes, carpentry and blacksmithing tools.

Unlike synthetic stones, Japanese natural stones consist of unique abrasive particles, almost without binding materials, which determine the nature of the grinding, smoothness and feel of sharpening.

Why choose natural stones?

- Unique structure – every stone is different.

- Natural form of abrasive particles – provides a smooth, clean cut.

- Delicate control – you can precisely control the sharpening process.

- Durability – Properly maintained stone lasts for decades.

- Traditional heritage – working with materials that have been used for centuries.

Main types of Japanese natural stones

1. Awasedo

Premium finishing stones for the final finishing of a knife or tool. Extremely fine and smooth.

2. Chu Nagura (中名倉)

Intermediate stone used before Awasedo. Has a medium-grained structure.

3. Koma Nagura (細名倉)

Used to prepare the stone surface and generate a gentle suspension.

4. Botan, Tenjyou, Mejiro Nagura

These are softer stones used in conjunction with harder stones to create suspension and refine the final edge.

5. Congo-Do (金剛覦)

A very hard and rough stone used for the basic shaping of a knife.

The most famous mines

Kyoto region:

- Nakayama – is famous for its highest quality finishing stones.

- Ohira – valued for its soft Awasedo.

- Shobudani – both hard and soft stones can be found.

- Atagoyama – one of the oldest mines, often of large dimensions.

- Ozuku – well-known very hard and very sharp stones.

- Takashima – valued for their gentle work.

Each mine has its own unique abrasive structure and stone character.

How to choose a Japanese natural sharpening stone?

1. Intended use

Are you sharpening a kitchen knife, razor or carpentry tool?

2. Stone hardness

Softer stones are better suited for hard steel and intermediate stages. Harder stones are better suited for softer steels or for sharp final edge finishing.

3. Level of abrasiveness

From coarse (for initial shaping) to ultra-fine (for final finishing).

4. Stone size

The larger it is, the more comfortable and durable it is.

5. Origin and reliability

It is important to know the mine and the results of the stone testing.

How to use Japanese natural sharpening stones?

- Moisten the stone (some require soaking).

- If necessary, prepare the surface with a nail file or smoothing stone.

- Sharpen a knife or tool in a continuous motion.

- Regularly remove accumulated suspension if it forms excessively.

- After use, rinse and dry naturally.

Care and storage

- Never keep a stone in water permanently.

- Protect from direct sunlight.

- After use, allow to dry without additional heating and avoid sub-zero temperatures.

- Smooth the surface from time to time.

Japanese Natural Sharpening Stones 2025 Trends

- The priority of authenticity – more and more buyers are looking for stones with video tests and known origins.

- Limited quantities – most of the old mines closed in the middle of the last century, so the remaining stones are becoming more expensive.

- Trading through niche platforms – such as jnats.eu.

- Local testers' ratings – customers are looking for tested and evaluated stones.

- Stone collecting – Japanese stones become an investment object.

Conclusion

Japanese natural sharpening stones are more than just a tool. They are a tradition, an art, and a heritage. A properly selected and maintained stone will not only give your knife or tool a flawless blade, but will also make the sharpening process enjoyable. When choosing, it is important to consider the origin, type, hardness, and abrasiveness of the stone, as well as a reliable supplier.