Although the production volumes of natural Japanese honing stones are very low, there are many people who use them in search of a finish that can only be achieved with natural honing stones. In this article, Jun Watanabe, an expert from the traditional knife brand Mitsuhide Sakai, will explain the characteristics of natural sharpening stones by region and how to choose them.

INDEX

- What is natural honing stone?

- The charm of natural stones

- Advantages of sharpening with a natural sharpening stone

- The difference between natural and artificial honing stone

- Natural sharpening performance

- Performing artificial sharpening

- Origin of natural whetstones

- Natural stone from Kyoto

- How to choose a natural sharpening stone

- Tips for natural sharpening

- Things to consider when choosing natural sharpening stones

- Terms for Natural Japanese Sharpening Stones

- What is natural honing stone?

- Nature's treasures, created over the eternity of the planet

Jnats (Japanese Natural Stones) are natural stones that have been mined over a long period of time, from hundreds of millions of years to the present day, from geological layers formed from sedimentary rocks and tuff piles.

The properties of Japanese honing stone vary depending on the region in which it is quarried, and the result of the work varies accordingly.

The natural sharpening stones give the knife a nicer finish and the delicately finished edge of the blade gives the cut part a beautiful look, making it a favourite with sharpening enthusiasts.

The charm of natural stones

I think the attraction of natural stones is that there are mechanisms at work that cannot be fully explained, even in the world of modern science.

They have a different molecular structure to natural and artificial materials, and the structure itself changes, giving a different result each time.

For this reason, the more you work on it, the better the finish, and I think that is why it arouses the curiosity of amateurs.

Advantages of sharpening with a natural sharpening stone

It all depends on the abrasive properties of the stone. Even artificial sharpening stones can cut well if sharpened by a skilled person, and in some cases the finished blade may appear sharper.

I think that just being able to cut well and having a good sharpness of the line between hard and softer steel (Chamon) are two different things.

When it comes to the cutting result, the taste of the cut food varies. I think this is the real benefit of sharpening with a natural sharpening stone.

The difference between natural and artificial honing stone

What is the difference between sharpening stones used to sharpen the same knife?

Advantages of sharpening natural stone

Sharpening performance - if you take your time sharpening, you will get a good blade.

- Shallow scratches on the edge of the blade

- Maintains sharpness for longer

- Can be removed immediately by grinding "before the hairline"

Polishing performance - buffs right down to the bottom, giving it a shiny finish.

・ Gives an internal clouding effect that highlights the blade, the soft metal and the line between them.

Finishing characteristics: high precision due to strong cutting edge hardening effect

- Rust-resistant

Brightness Effect - exceptional brightness

- Long cutting times

- Saves sharpening effort

- Long cutlery life

Features of artificial stone

Cutting efficiency - quick sharpening

- Deep 'scars' on the edge of the blade

- Easy blade restoration

- Harder to remove the gate

Polishing performance: can polish a surface to a mirror finish.

Bright shine

Finishing performance - accuracy is poor because the cutting edge hardens slowly.

- Easier to rust

Brightness effect - cuts well at first

- Loses its original sharpness more quickly

- Re-sharpening takes time

- Long cutlery life

The above differences exist between natural and artificial sharpening stones. Even if there are differences between natural and artificial materials, why are there so many differences even though it is the same sharpening tool? It is because of the abrasive grains, which are the most important part of sharpening stones.

Artificial sharpening stones are mainly made using abrasive grains such as silicon carbide (SiC) and aluminium oxide (Al₂O₃), but these abrasive grains are hard and have sharp edges, which damage the metal more than necessary. Recently introduced diamonds and elbors further weaken the blade, but have a high working speed and are good on steels with many alloying elements (CPM 15V, ZDP-189, CPM 125V, etc.)

Even when using a very fine-grained finishing whetstone, scratches and large depressions remain.

Natural sharpening stones have rounded abrasive grains, and each time they are polished, the abrasive grains are crushed into finer particles, resulting in smaller scratches and a finer finish.

Are artificial whetstones inferior?

I used to think that natural sharpening stones were better, but now I can't give anyone an advantage because their properties are different.

On the other hand, artificial sharpening stones have the advantage of high sharpening efficiency, allowing them to sharpen the tool quickly.

In addition, the most important feature of artificial sharpening stones is that the roughness standard based on the calculation is firmly established and can therefore be adapted to the purpose of human sharpening.

For this reason, artificial sharpening stones have an appeal that natural sharpening stones do not: "You can quickly finish at the desired sharpness, which is easy to predict in advance".

Origin of Natural Japanese Sharpening Stones

Natural whetstones are extracted from nature and have been distributed from all over the country.

Name Characteristics of the region

Omura Whetstone Wakayama Prefecture

It is called the Omura Stone because it was originally mined in Omura, Nagasaki, but after mining was completed, it was quarried in the Shirahama district of Wakayama Prefecture.

As it is sandstone, it is a grey coloured point that has been used as a rough sharpening stone.

Hirashima Whetstone Nagasaki Prefecture

The stone is quarried on a mountain in the Hirashima district of Nagasaki Prefecture.

It is a sandstone sharpening stone, which produces a lot of sand and dirt and is therefore used as a coarse abrasive.

Aoto Kyoto Prefecture

This is a medium fineness sharpening stone for the voodoo sharpening process, quarried in the Tanba area of Kyoto, and is able to maintain its sharpness for a long time, with a beautiful lustre on the finished surface, making it one of the highest valued quality stones used for polishing Japanese swords.

Amakusa Whetstone Kumamoto Prefecture

This medium-sized stone is still being excavated in Oyano, Kumamoto Prefecture.

Depending on the class, it is divided into "Jōpaku" (Bisui), "Nakapaku" and "Tora" (Akatora).

Iyoto Ehime Prefecture

A soft, easily sharpened stone quarried in the Ijo region of Ehime Prefecture, it was also used for sharpening Japanese swords.

Shiranakurato Aichi Prefecture

It is a medium-white whetstone quarried in the Mikawa area of Aichi Prefecture and, in addition to its use as a whetstone, it has long been used as a donor for whetstone suspension.

Goto Kyoto Prefecture

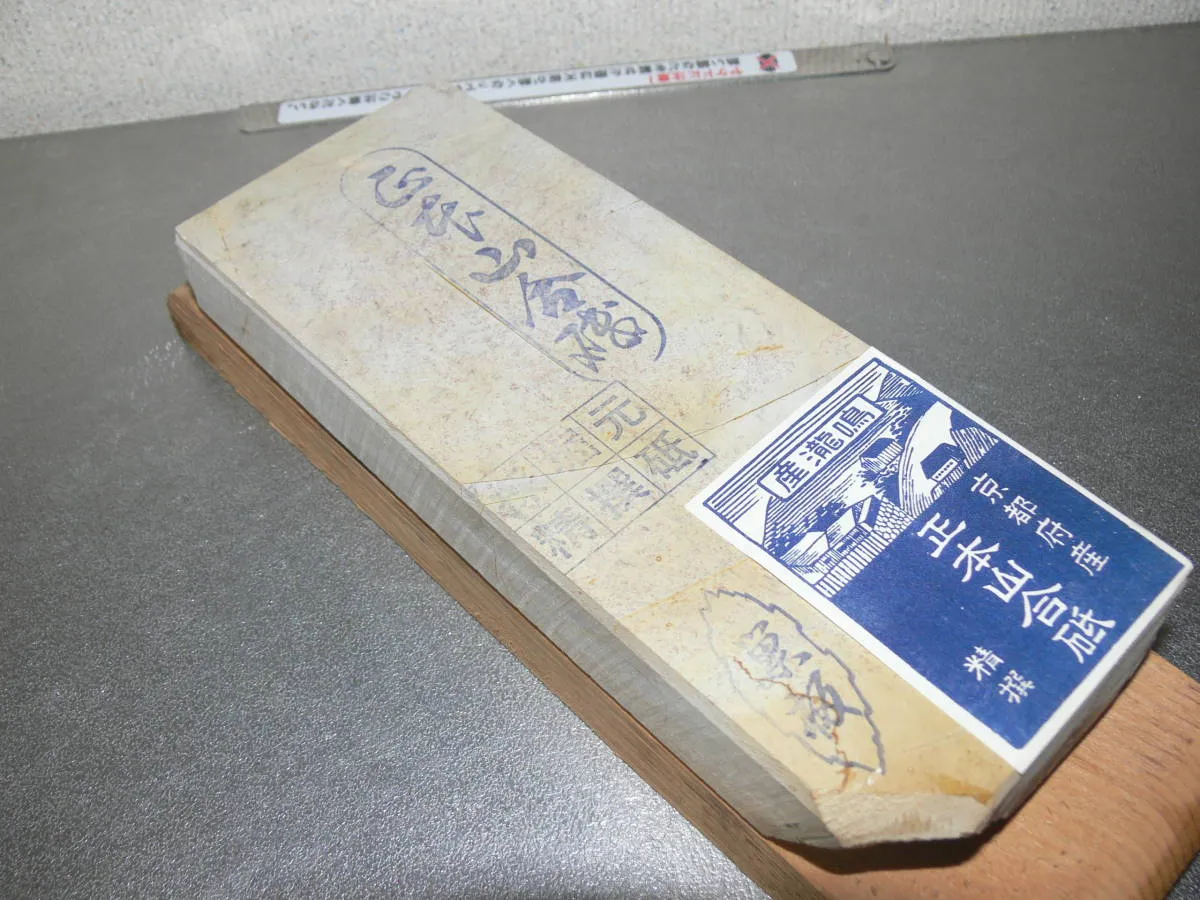

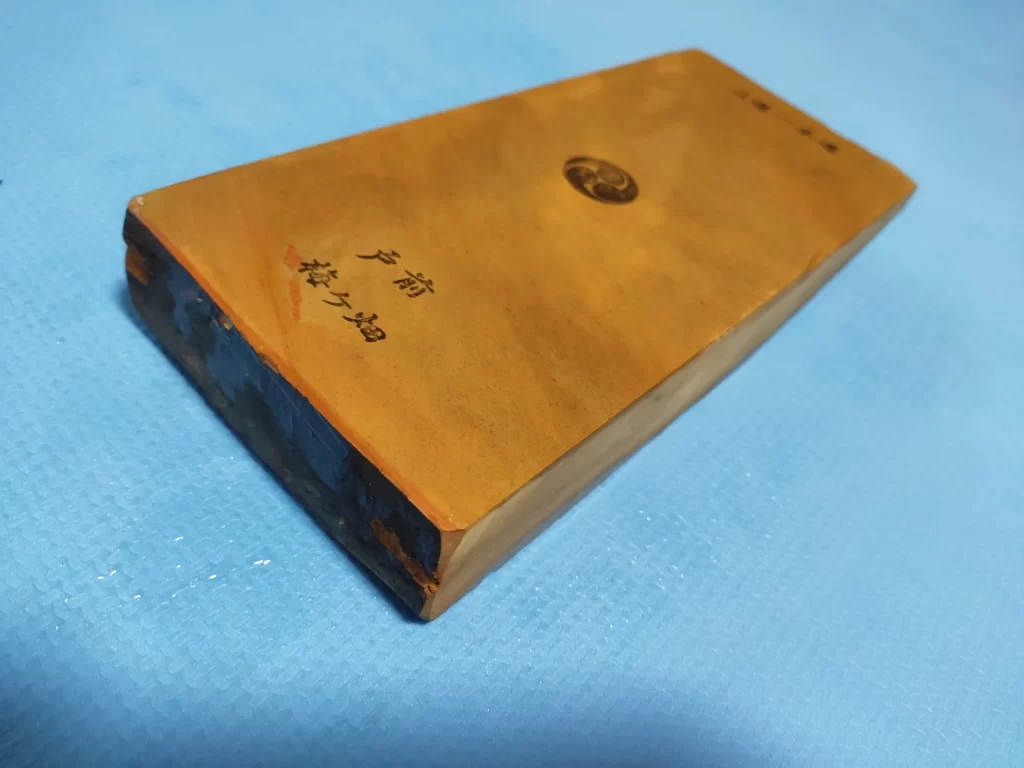

It is the highest quality cut stone, quarried on a mountain in Kyoto Prefecture, and this fine-grained finishing stone is produced only in Kyoto, the only place in the world.

The characteristics vary depending on the mountain of stones, and enthusiasts come from all over the world.

The pebbles are mined from different regions and their properties vary from region to region.

The quality of quarried cut stone in Kyoto is excellent, and its attractive finish is highly appreciated by amateurs.

Natural stone from Kyoto

Although most of the mines are now closed, originally natural points were mined all over the country, but to this day, the highest quality sharpening stones are produced in Kyoto - and this will be Aoto.

How to choose a natural grinding stone

When it comes to choosing a natural abrasive stone, it's hard to be precise.

The only way to choose is to see it with your own eyes.

Artificial grinding stones are divided into detailed specifications so you can choose the one that suits you.

However, natural Japanese honing stones come from natural mines, and frankly, the quality of the stone will vary even if the location where it is mined is only a few centimetres different.

Therefore, to choose a good natural grinding stone, you need to have a solid knowledge of grinding stones and an eye that can distinguish colour and layers.

It's like meeting people for the first time in your life.

Tips for choosing natural grinding stones

1. Trader (quality guaranteed if the trader is reliable)

2 Hardness (hardness, abrasive grain size and evenness)

3 Price (please estimate your budget)

4 Priority (if you like it, it's worth a try)

Then go to the shop and choose a natural abrasive stone that is well versed in sanding and suited to your purpose (hardness is particularly important).

Also, quality sharpening stones are expensive, but if you like them, I think it's worth the effort to try them out.

Things to consider when choosing natural grinding stones

- Hardness

- The faster it absorbs water, the softer it is; the slower it absorbs water, the harder it is.

- The higher the impact sound, the harder it is, and the lower the sound, the softer it is.

- The heavier it is in the hand, the harder it is, and the lighter it is, the rougher and softer it is.

- The whiter the suspension, the softer it is, and the darker, the harder.

- If it's too hard, you'll work slowly, and if it's too soft, you'll get bored and find it hard to achieve a high sharpness.

- Even if the stone looks too hard, it can be softened by sharpening with Nagura. This will also smooth the surface and therefore sharpen better without scratching the surface.

How to assess quality?

- There are no problems with uniformity or shape.

- Even if there are irregularities, it should be assessed whether they are rougher than the main area.

- Check for coarse abrasive grains.

- If you use Nagur on it, the stone will not shed its suspension.

- Even if the stone is hard, it should be sufficiently "sticky".

- Easy to use and suitable for knife

- Although expensive, the quality should be satisfactory