What are carbides in knife steel?

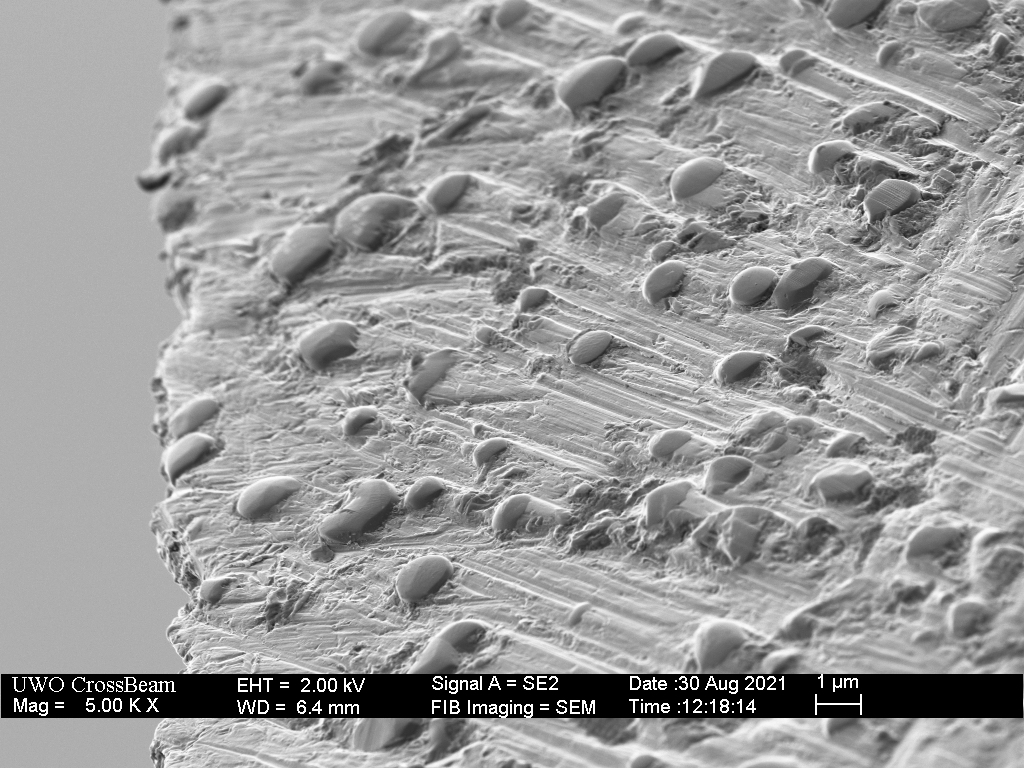

Carbides are hard microparticles formed when carbon is combined with other elements in the alloy, such as chromium, vanadium, tungsten or molybdenum, during the hardening of steel. These particles are much harder than the steel matrix itself and strongly influence the cutting properties:

- Abrasion resistance

- Cut quality

- Sharpening complexity

- Keeping the edge

The more carbides and the harder and more evenly distributed they are, the longer the blade stays sharp. However, coarse carbides can compromise edge stability, especially when sharpening on small stones or at extremely sharp angles.

Value of carbide size

The size of carbides is usually measured in microns (μm). This is a very important parameter because:

- Fine carbides (0,5-3 μm) allow a smoother and sharper cut, making it easier to sharpen to a very sharp edge.

- Coarser carbides (5-20 μm) offer better wear resistance but can make the cut rougher and make sharpening more difficult.

Modern powder steels allow carbides to be distributed evenly and reduced in size, while maintaining a high particle content and improving the balance of properties.

Table of carbide sizes and properties for knife steels

| Steel | Carbide size (μm) | Dominant carbide | Abrasion resistance | Ease of sharpening | Cut quality |

|---|---|---|---|---|---|

| Shirogami #1/#2 | 0,5-2 | Fe₃C | Medium | Very good | Excellent |

| Aogami #1/#2 | 1-3 | Fe₃C, Cr₇C₃ | High | Good | Excellent |

| VG-10 | 2-5 | Cr₇C₃ | High | Medium | Good |

| 440C | 5-15 | Cr₇C₃ | High | Medium-Ordinary | Medium |

| D2 | 5-20 | Cr₇C₃ | Very high | Poor | Medium |

| CPM S30V | 1-4 | V₄C₃ | Very high | Good | Excellent |

| CPM S35VN | 1-4 | V₄C₃, NbC | Very high | Good | Excellent |

| CPM S90V | 1-2 | V₄C₃ | Extremely high | Medium | Excellent |

| CPM M4 | 1-3 | Mo₂C, V₄C₃ | Very high | Medium | Excellent |

| M390 | 1-3 | V₄C₃, Cr₇C₃ | Extremely high | Good | Excellent |

| ZDP-189 | 2-4 | Cr₇C₃ | Very high | Poor | Excellent |

What to know when choosing steel?

- If quality of cut and ease of sharpening are a priority, fine carbide steels (Shirogami, Aogami, CPM S30V, S35VN) are a good choice.

- If long sharpness retention and wear resistance are important, powder steels with a high vanadium or carbon carbide content (CPM S90V, M390, ZDP-189) should be chosen.

- D2 and 440C are durable and popular, but the coarser carbides make them more difficult to sharpen and the cut quality is average.

- Powder metallurgy steels (CPM series, M390) have a high carbide content, but small size and uniform distribution, and are often considered the state-of-the-art knife material.

Conclusion

The size of the carbide is one of the most important factors in determining the performance of a knife. The smaller the carbides and the more evenly distributed they are, the sharper the knife will be, the better it will cut fine materials, the easier it will be to sharpen and the more pleasant it will be to use.

When choosing a knife or its manufacturing material, it is not only worth looking at the hardness (HRC) or rust resistance, but also at which carbides predominate in the steel, how many there are and what size they are.