Technical jasper (jašma - яшма) is a green or dark green grinding stone. It is one of the secretory varieties of crystalline rocks, consisting mainly of quartz, chalcedony and impurities of other minerals (epidote, actinolite, chlorite, mica, pyrite, iron and manganese oxides and hydroxides). Jasper is of either sedimentary or volcanic origin. Approximate composition of jasper: quartz and chalcedony (SiO2) 80-95%; aluminum oxide (Al2O3) and iron oxide (Fe2O3) up to 15 %; calcium oxide (CaO) - 3-6% (and others). It should be noted that quartz and chalcedony have the same chemical formula (SiO2) and differ from each other only in appearance.

Industrial jasper is mined in areas where flaky or layered rocks are found. Technical jasper primarily includes quartz and chalcedony-quartz, which are varieties of banded or banded jasper. Most often, this type of jasper has a green color, which is directly related to the color of the mud emitted by underwater volcanoes. Over millions of years, they erupted through large amounts of silica as lava, then settled as silica, and then, also over millions of years, underwent a process of recrystallization. Jasper can also be of secondary origin from organic raw materials. An example is petrified trees that have been transformed over millions of years into various forms of quartz, including jasper. Also, the secondary formation of jasper can occur from certain types of living organisms: sponges, algae, etc.

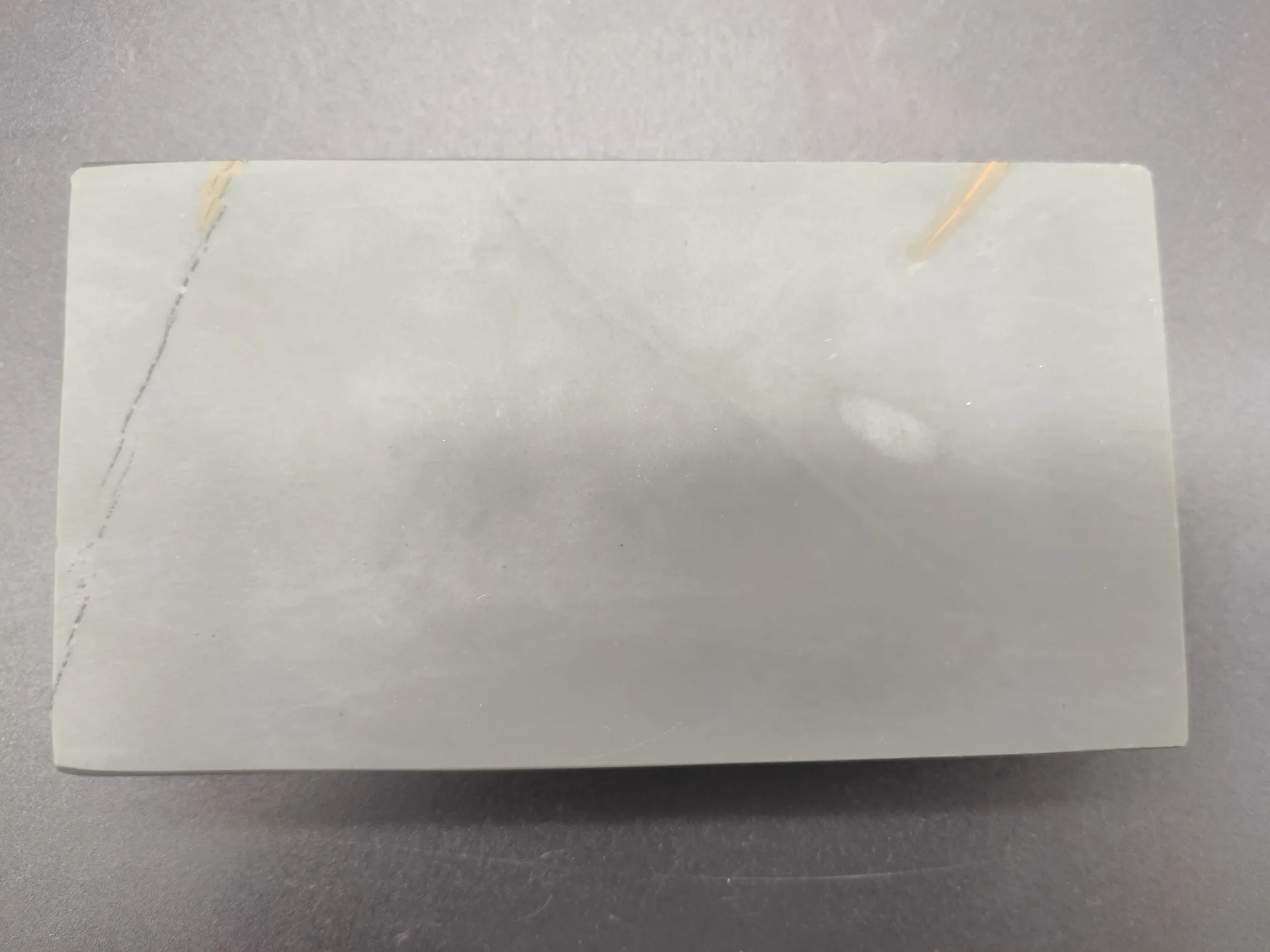

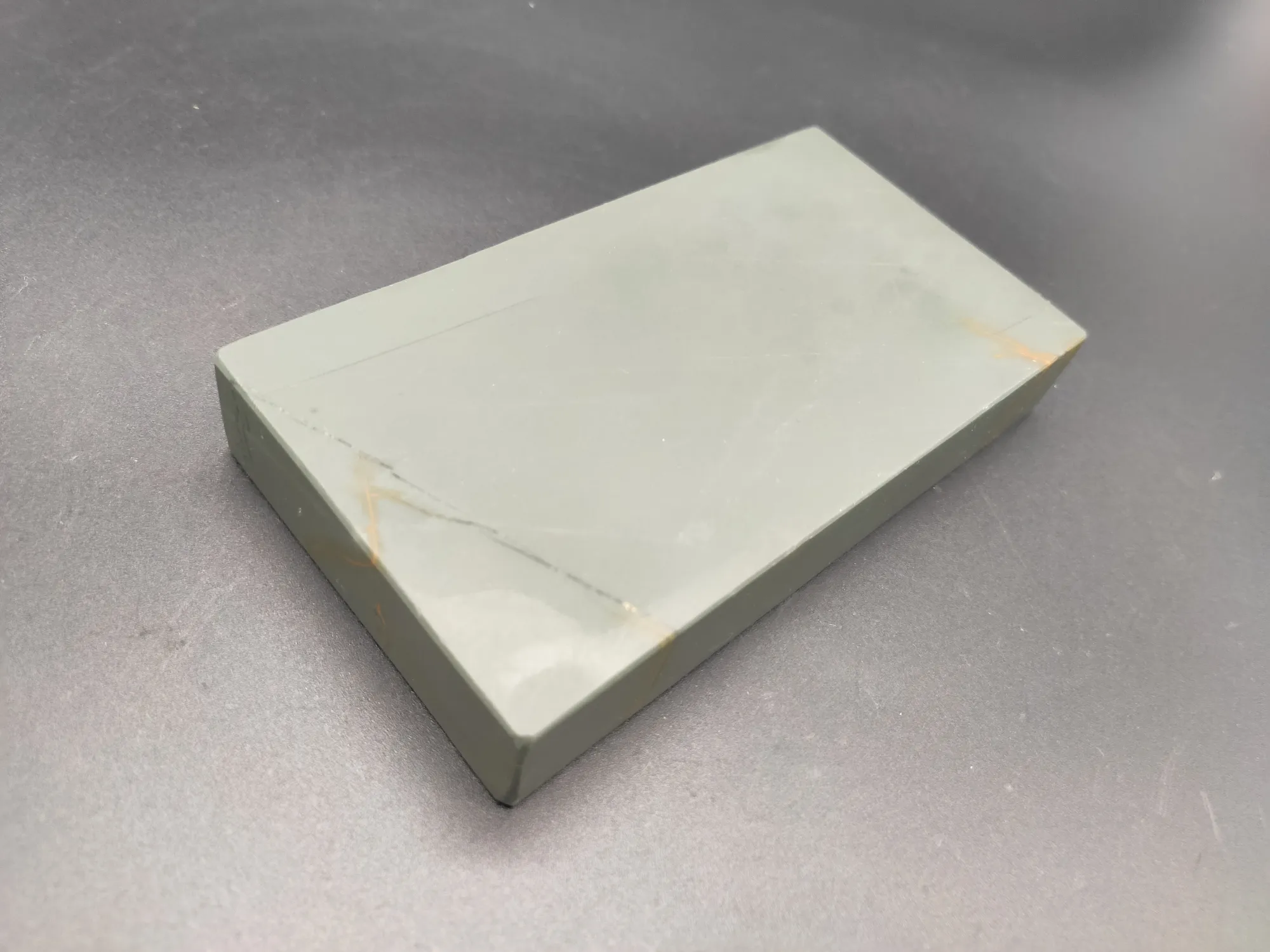

Unlike other types of jasper, industrial jasper has a much higher density because it usually consists of 80-90% of quartz and 10-15% of chlorite (a mica-like mineral from the layered silicate subclass) with an admixture of epidote. , thiosite and clay. Jasper has a combed fracture, similar in appearance to the inner surface of shells. In addition to ordinary jasper, spotted jasper is also classified as technical jasper. According to the number and density of spots, spotted jaspers are divided into several types: weakly spotted, dense, fuzzy, yellow spotted, etc. At the same time, a smaller number of spots indicates a greater uniformity of jasper, which is directly related to its work efficiency.

The more uniform the jasper, the better the quality of the sharpening stone, the sharper the blade line and the more aggressive the knife cut after sharpening.

In industry, technical jasper is mainly used as a raw material, as well as as finishing and decorative stones. In fact, the lowest quality gemstones, unsuitable for crafts, souvenirs and tableware, are called "technical jasper". Processing shafts, cups, supporting prisms for measuring instruments, etc. are made from them. This type of jasper is characterized by maximum strength, hardness, uniformity, and most importantly, the repeatability of the properties of the stone mined in one deposit.

There are quite a lot of industrial jasper deposits in Russia. Gray and grayish-green jaspers are mined in the Kalkan deposit, Kushkuldinskoye, Anastasevskoye, Muldakaevskoye, Malomuinakovskoye and Naurazovskoye deposits, where jasper of other shades are found, are also considered quite large. Abroad, there are deposits of industrial jasper in India, Japan, Germany, France, Uzbekistan and Tajikistan.

In sharpening, industrial jasper is used as a finishing and polishing stone. It shows the highest efficiency when working with carbon steel such as Aogami, Shirogami, R6M5, U7, 65G, etc. After jasper, they get a uniform matte surface with an aggressive cut. The stone also sharpens powder steels RWL, CPM S35VN, S30V, ELMAX with a hardness of up to 63HRC. The stone is designed to work with oil, but can also work with water. However, working with water results in a rougher blade surface than with oil. Experienced sharpeners, comparing technical jasper with washita or Arkansas, note the finer work of these stones and the sharper knife cut after sharpening. The knife with a technical jasper sharpening finish provides maximum results when working with wood, meat and other dense materials.

Technical jasper is not classified as a rare stone that can only be purchased by sharpening professionals. It is a common and widely sold stone. Jasper is sold both in large rectangles for hand sharpening and in "apexoid" sized pieces for standard abrasive holders. Having overcome a long journey of several centuries, he still does not give up his position.

Reviews

There are no reviews yet.